- Survey No.19, Plot No. 29, Nr. Perfect Ceramic, N/H. 8/B, Gondal Road, Vavdi, Rajkot (Guj.) - 360 004.

- rudrakshtpl@yahoo.com

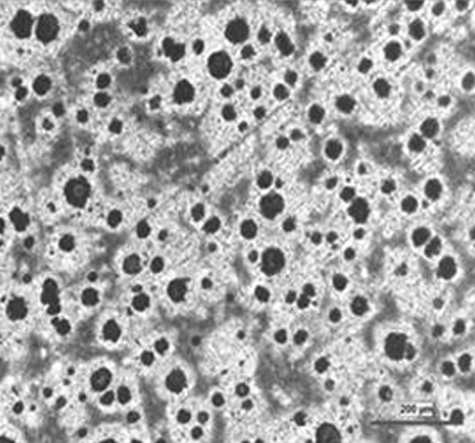

Rudraksh Technocast Is one of the premier foundries in India, Located in Rajkot-Gujarat, producing high quality S.G.Iron (NODULAR CAST Iron OR DUCTILE Iron) castingfor customer around the world. We are equipped with State-of-Art Technology, Melting Shop, Mobile shop, Core Shop, Fettling & Grinding facility and Chemical plus Physical labroratory to cast and test components with stringent merallurgical and quality requirements. We are engage is S.G.I. Casting production business since 2005 and it has motivated us to extend our foundry business skills and expertise in S.G. Iron.

Our annual production capicity is 1200 MT. We have a capicity to cast a single component weight range from 1 Lbs (0.454 kg) to 660 Lbs (330 kg).

| Country | Standard | Equivalent Grades of Ductile iron (SG Iron, Nodular Graphite Iron) | ||||||

| ISO | ISO 1083 |

400-15 400-18 |

450-10 | 500-7 | 600-3 | 700-2 | 800-2 | 900-2 |

| China | GB 1348 | QT400-18 | QT450-10 | QT600-3 | QT700-2 | QT800-2 | QT900-2 | — |

| USA | ASTM A536 | 60-40-18 |

60-42-10 65-45-12 |

70-50-05 |

80-55-06 80-60-03 |

100-70-03 | 120-90-02 | — |

|

Germany Austria |

DIN 1693 | GGG40 | — | GGG60 | GGG70 | GGG80 | — | — |

| European | EN 1563 |

EN-GJS-400-15 EN-GJS-400-18 |

EN-GJS-450-10 | EN-GJS-500-7 | EN-GJS-600-3 | EN-GJS-700-2 | EN-GJS-800-2 | EN-GJS-900-2 |

| Japan | JIS G5502 | FCD400 | FCD450 | FCD600 | FCD700 | FCD800 | — | — |

| Italy | UNI 4544 | GS370-17 | GS400-12 | GS600-2 | GS700-2 | GS800-2 | — | — |

| France | NF A32-201 | FGS370-17 | FGS400-12 | FGS600-2 | FGS700-2 | FGS800-2 | — | — |

| UK | BS 2789 | 400/17 | 420/12 | 600/7 | 700/2 | 800/2 | 900/2 | — |

| India | IS 1865 | SG370/17 | SG400/12 | SG600/3 | SG700/2 | SG800/2 | — | — |

| Spain | UNF | FGE38-17 | FGE42-12 | FGE60-2 | FGE70-2 | FGE80-2 | — | — |

| Belgium | NBN 830-02 | FNG38-17 | FNG42-12 | FNG60-2 | FNG70-2 | FNG80-2 | — | — |

| Australia | AS 1831 |

300-17 400-12 |

— | 500-7 | 600-3 | 700-2 | 800-2 | — |

| Sweden | SS 14 07 | 0717-02 | — | 0732-03 | 0737-01 | 0864-03 | — | — |

| Norway | NS11 301 |

SJK-400.3 SJK-400 |

— | SJK-500 | SJK-600 | SJK-700 | SJK-800 | |

| Country | Standard | Equivalent Grades of Grey Iron (Gray Cast Iron) | ||||||

| ISO | ISO 185 | 100 | 150 | 200 | 250 | 300 | 350 | - |

| China | GB 9439 | HT100 | HT150 | HT200 | HT250 | HT300 | HT350 | - |

| USA | ASTM A48 | - |

NO.20 NO.25 |

NO.30 | NO.35 |

NO.40 NO.45 |

NO.50 |

NO.55 NO.60 |

|

Germany Austria |

DIN 1691 | GG10 | GG15 | GG20 | GG25 | GG30 | GG35 | GG40 |

| European | EN 1561 | EN-GJL-100 | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 | |

| Japan | JIS G5501 | FC100 | FC150 | FC200 | FC250 | FC300 | FC350 | - |

| Italy | UNI 5007 | G10 | G15 | G20 | G25 | G30 | G35 | - |

| France | NF A32-101 | - | FGL150 | FGL200 | FGL250 | FGL300 | FGL350 | FGL400 |

| UK | BS 1452 | 100 | 150 | 200 | 250 | 300 | 350 | - |

| India | IS 210 | - | FG150 | FG200 | FG260 | FG300 | FG350 | FG400 |

| Spain | UNF | - | FG15 | FG20 | FG25 | FG30 | FG35 | - |

| Belgium | NBN 830-01 | FGG10 | FGG15 | FGG20 | FGG25 | FGG30 | FGG35 | FGG40 |

| Australia | AS 1830 | - | T150 | T220 | T260 | T300 | T350 | T400 |

| Sweden | SS 14 01 | O110 | O115 | O120 | O125 | O130 | O135 | O140 |

| Norway | NS11 100 | SJG100 | SJG150 | SJG200 | SJG250 | SJG300 | SJG350 | - |

| Min. Tensile Strength (Mpa) | 100 | 150 | 200 | 250 | 300 | 350 | - | |

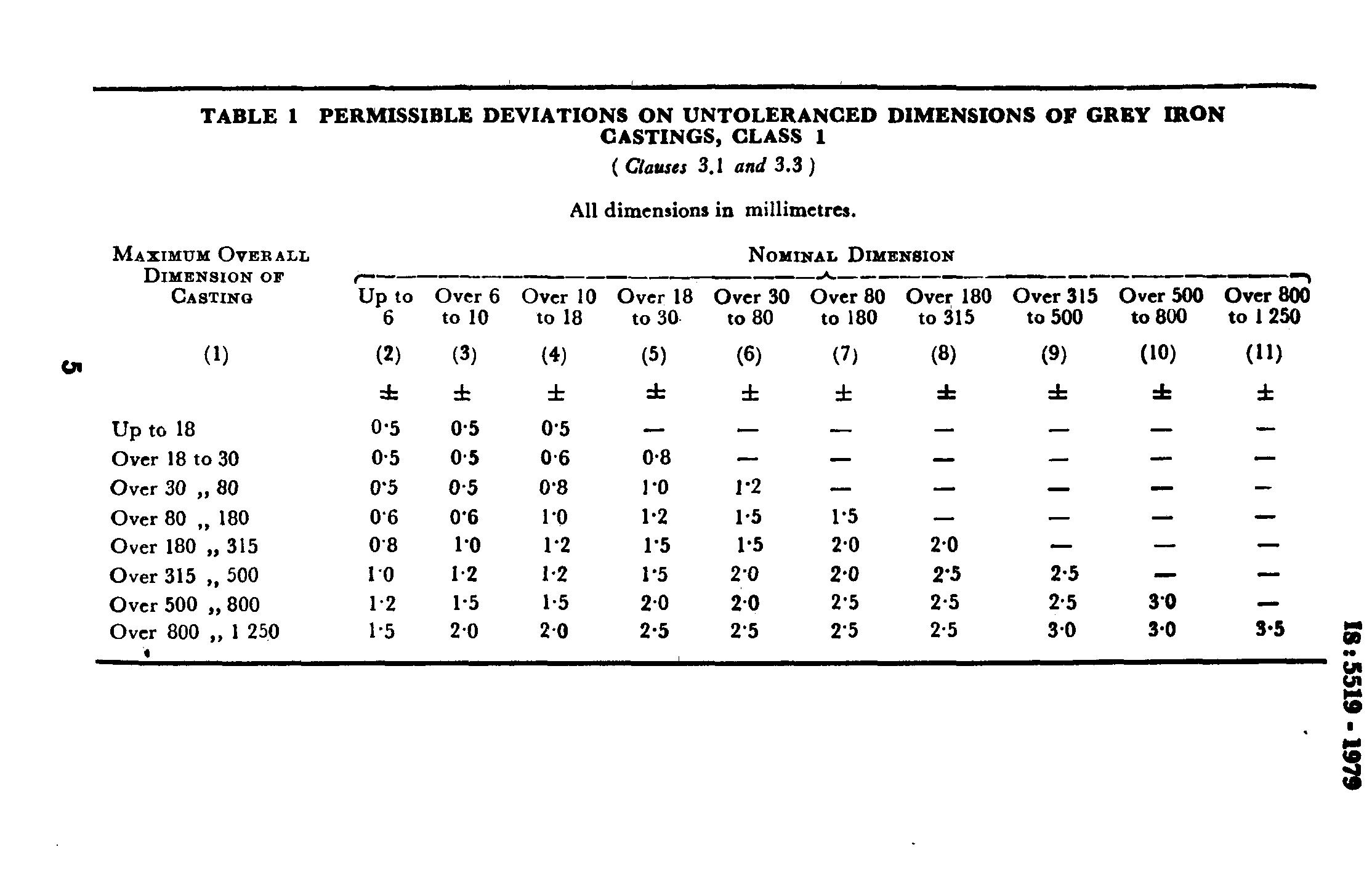

Permissible Devitions On Untoleranced Dimensions Of Grey Iron Castings, Class I

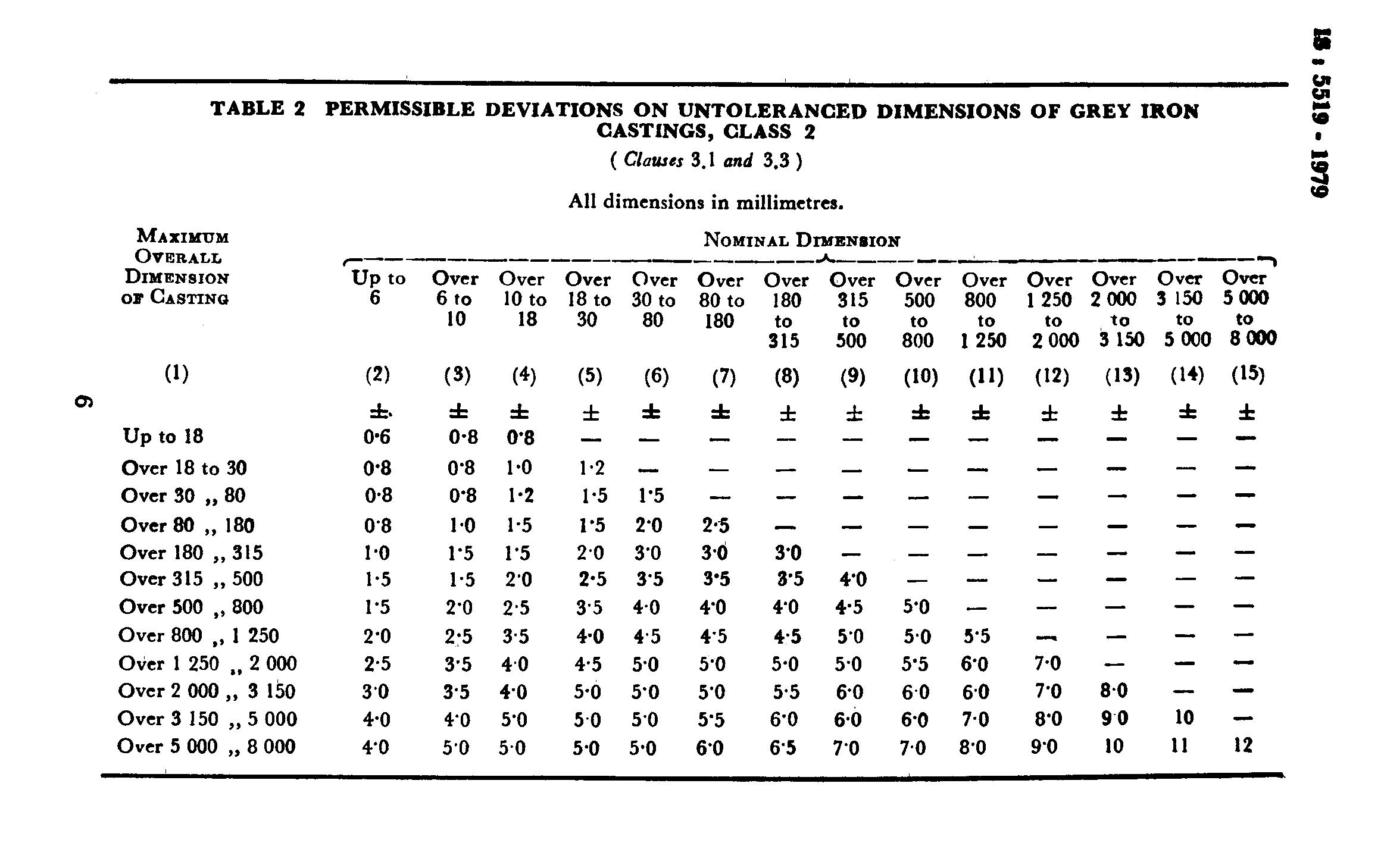

Permissible Devitions On Untoleranced Dimensions Of Grey Iron Castings, Class II

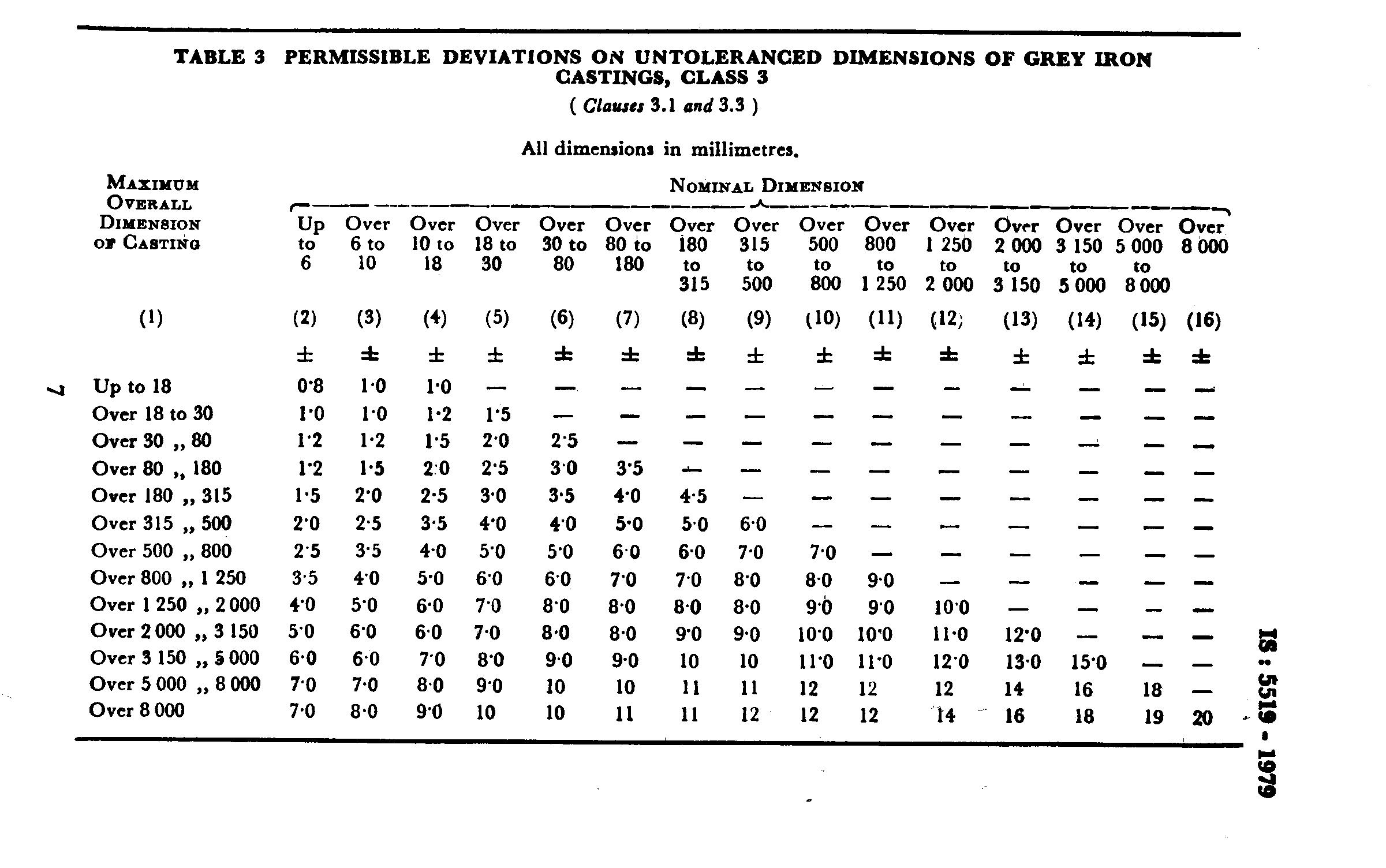

Permissible Devitions On Untoleranced Dimensions Of Grey Iron Castings, Class III

If you have any query about our product or us please leave a message.